Select Language:

Steel Manager III

About Steel Manager III

Improve Efficiencies, Generate Sales & Reduce Costs

STEEL MANAGER III IN THE CLOUD

Steel Manager III (SM3) is our Cloud Based, fully integrated metal service center software solution. Designed over nearly 40 years exclusively for the metals industry, you can be assured that SM3 can handle all the unique requirements of today’s metal service centers.

Steel Manager III is a completely integrated and comprehensive ERP solution with modern, user-friendly Windows screens and includes all the functionality today’s metal service centers require. SM3 includes full functionality in the areas of Inventory Management, Purchasing, EDI Integration, Quoting, Sales, Linear Nesting, Plate Nesting Integration, Inside Processing, Outside Processing, Production Scheduling, Picking, Shipping Manifest, complete Accounting, extensive Reporting, Barcoding, Customer Portal & eCommerce and much more.

The flexibility of SM3 makes it an ideal solution for all metal centers, whether you are a general line distributor, or focus on pipe & tube, valves & fittings, OCTG products, tool steel, bar, plate, flat rolled products, perforated and expanded metal, mesh, wire rope, specialty steel and structural steel, architectural metals, along with any other type of metal.

Here are just some of the many features within Steel Manager III

- Modern, user-friendly interface screens

- Very intuitive navigation

- Highly automated software

- Complete inventory control, including remnants

- Total visibility of both foreign and domestic material

- Fast quote and order creation

- Automatically capture processing costs

- Complete Traceability of inventory

- Automated Delivery of Material Test Reports (MTRs)

- Linear Nesting

- Sell Or Buy In Any Unit Of Measure

- Complete Bar Code Functionality

- Advanced Production Scheduling

- Shipping Manifest

- Detailed Document Tracking

- Plate Nesting

- eCommerce Customer Portal

- Task Manager

- Easy & quick report generation from hundreds of reports

- Automated Document Delivery by Email or Fax

Open Client Architecture

Our Open Client architecture allows users to connect to SM3 from any device, anywhere in the world with an Internet connection using Google Chrome or Microsoft Edge.

Streamline Your Metal Operations

Steel Manager III Highlights

- Inventory Control

- Purchasing

- Quotes & Sales Orders

- Production

- Shipping Manifest

- Reporting

- Integrated Accounting

- CRM Functionality

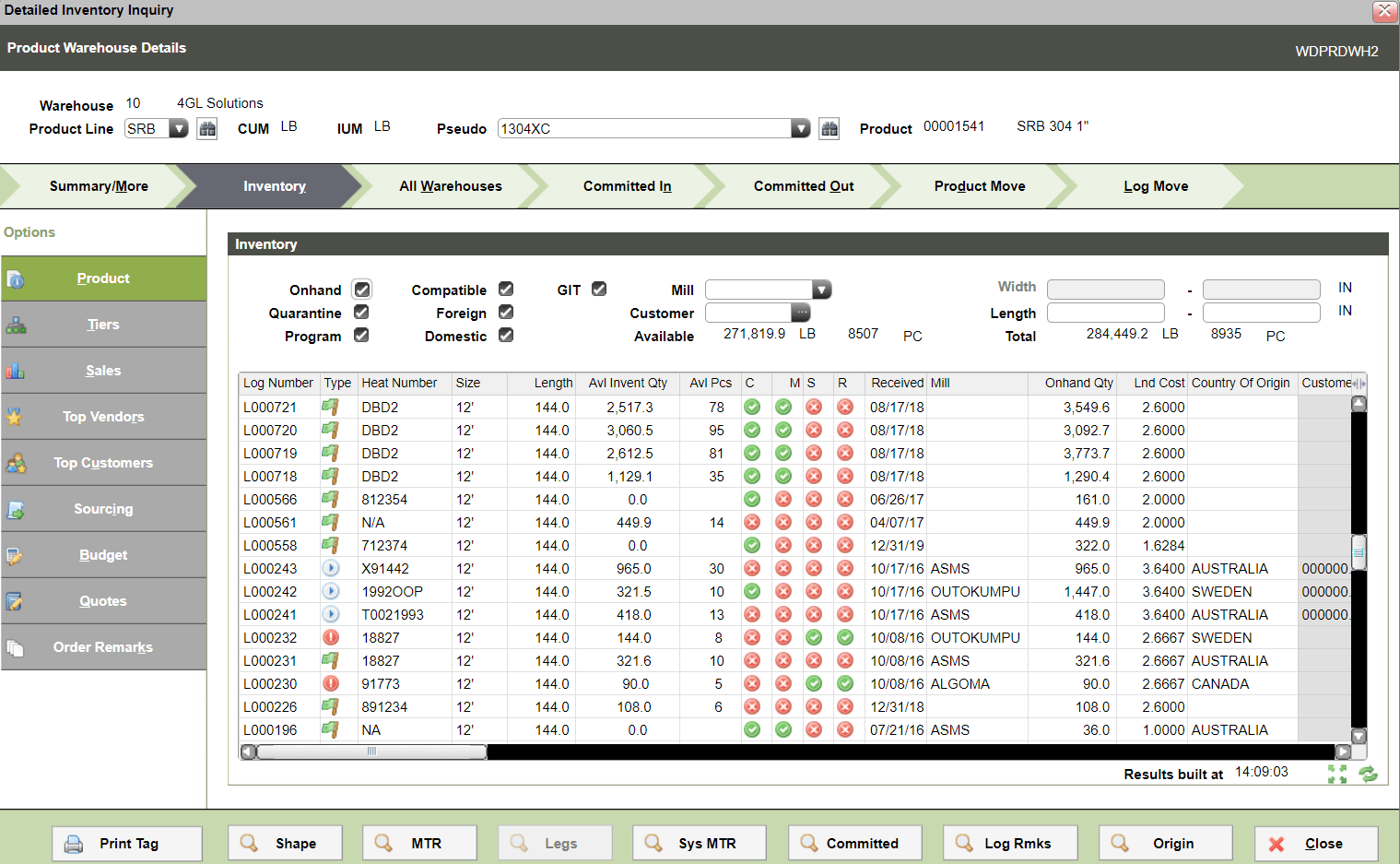

Inventory Control

- Total inventory control in real-time, including remnants

- Full traceability on all inventory

- Automated delivery of MTRs (Certifications)

- EDI (Electronic Data Interchange) capability

- Complete barcode functionality

- Variety of inventory management tools

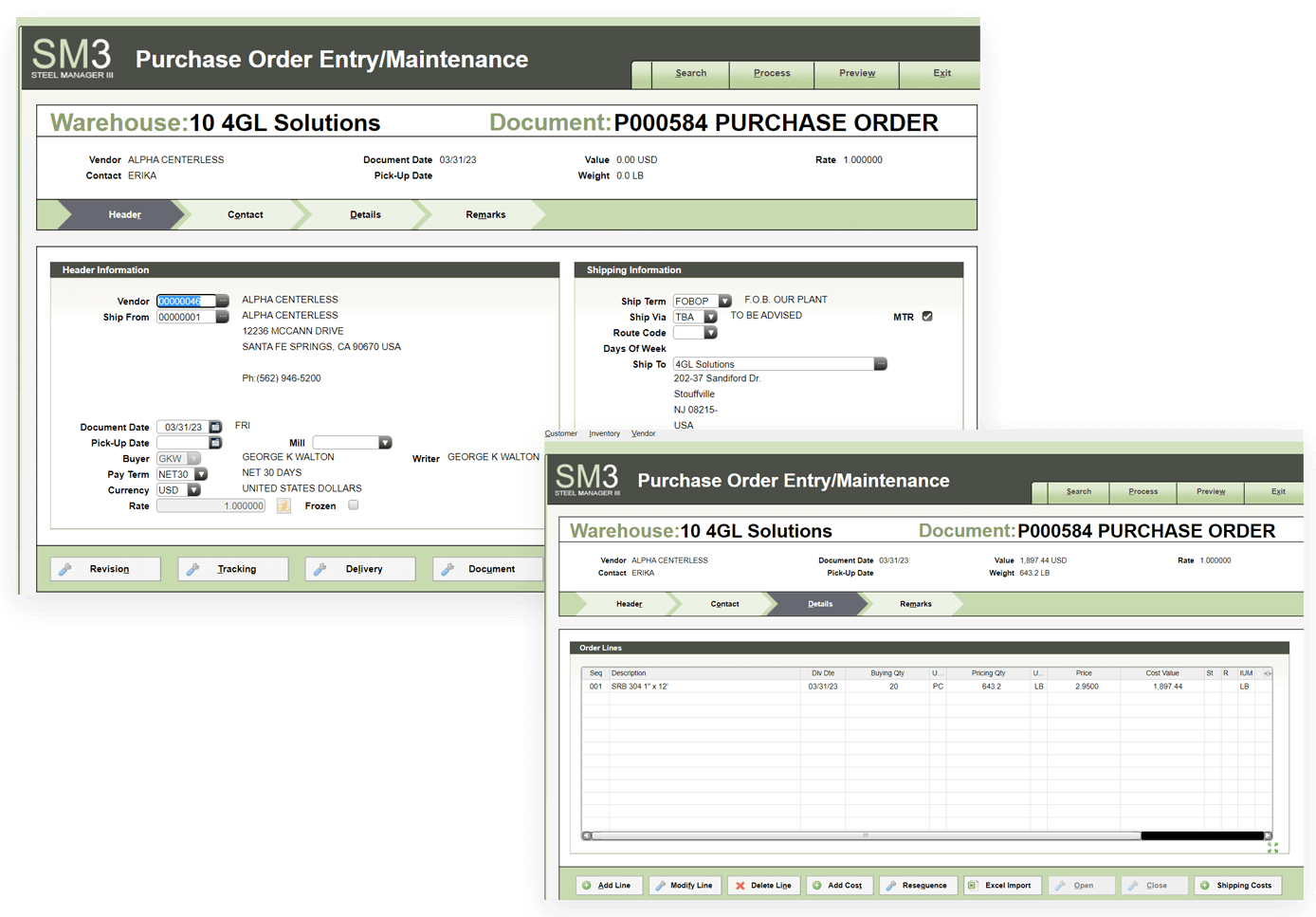

Purchasing

Multiple Remarks can be entered against the PO. and can be printed at the top of the first page only, at the top of every page, at the end of the document, or after every line item on the document.

- Automatically monitors usage of raw materials and finished goods

- Inventory Reorder reports

- Vendor sourcing program

- Import purchase orders from Excel

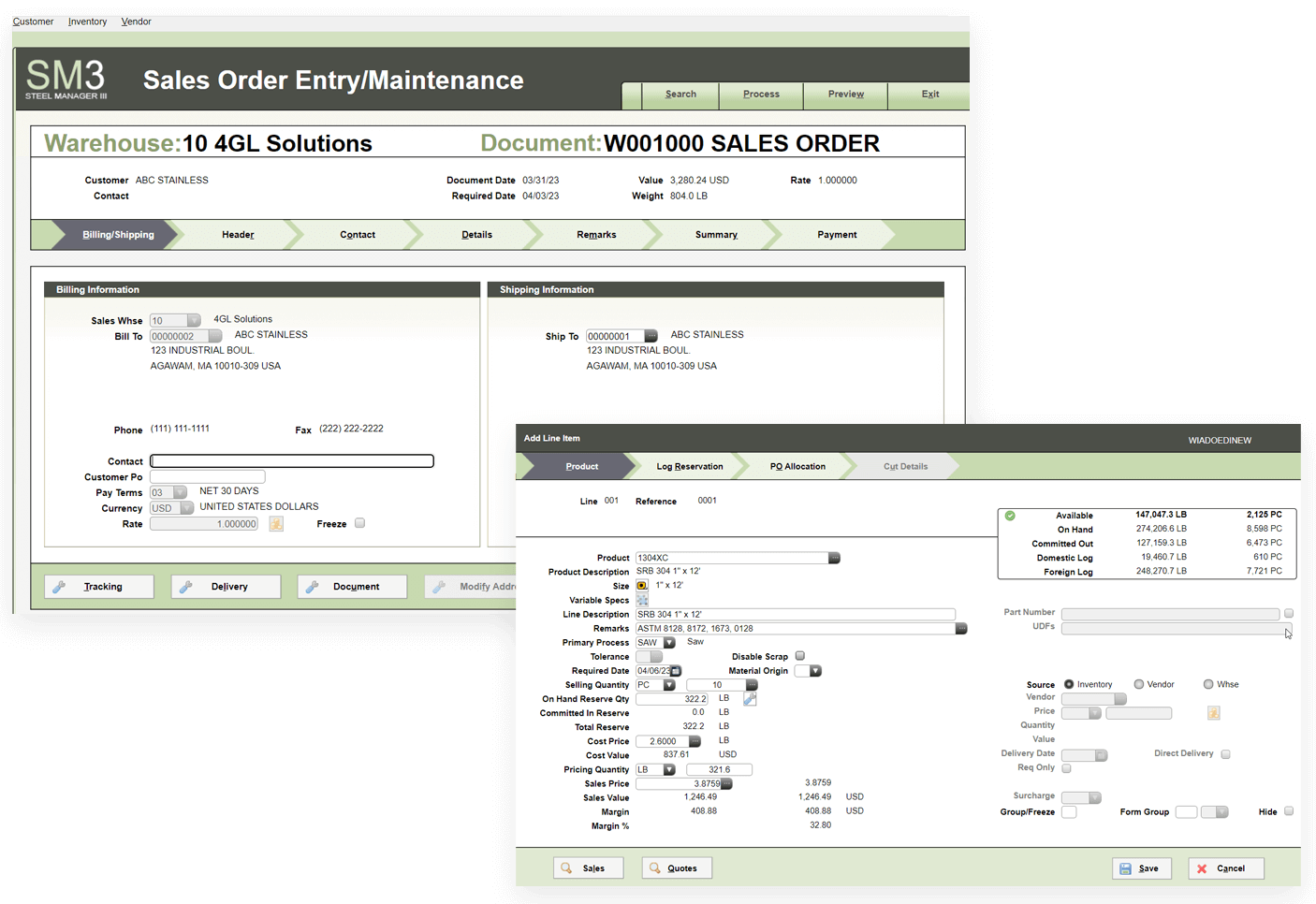

Quotes & Sales Orders

- Quick and easy quote & order creation

- Sales staff have real-time, instant access to all inventory items, in all locations

- Integrated quote follow-up screen

- Preview quotes & orders

- Quote or sell in any unit of measure

- Multi-currency

- Automatically capture processing costs on quotes and orders

- Excel import capability for both quotes and orders

- Order creation with customer parts

- Sophisticated price books

- Profitability checks

- Automatically Email quotes & orders to customers

Production

- Accommodates any inside or outside processing

- Advanced Production Schedule

- Filter columns by date, raw material etc.

- Plate nesting integration to SigmaNEST

- Attach a picture of plate drops to inventory items

- Integrated linear nesting capability

- Track processing time with handheld scanners

- Complete shipping manifest system

Shipping Manifest

- Orders are automatically added to the shipment manifest

- Schedule trucks by shipping route

- Barcode scan load confirmations

Reporting

- Over 300 standard reports

- Generate reports in seconds

- Export reports to Excel

- Receive automated reports in your Email in PDF format

- Management Dashboards showing key metrics

Integrated Accounting

- Accounts Receivable

- Accounts Payable

- General Ledger

- Credit controls on all orders

- Customer credit history

- Unlimited notes against customer

- Integrated cash book & bank reconciliation

- Ability to drill down to document level

- Multi-currency capability

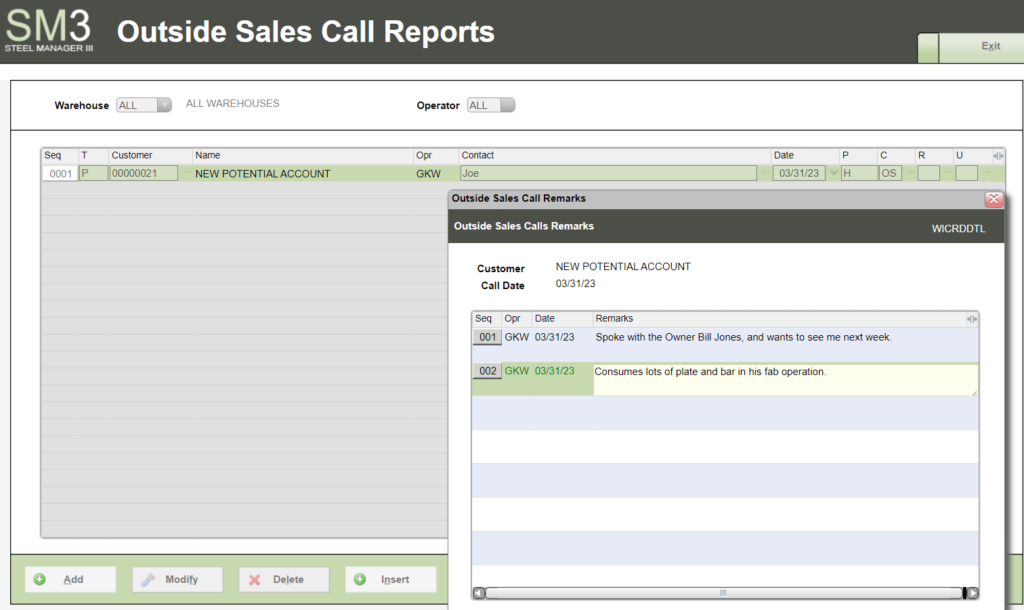

CRM Functionality

- Enter unlimited notes for customers, accessible by all staff

- Potential customer database

- Instantly view all quotes, and quotes that turned into orders

- View all open orders for the customer

- Schedule follow-up dates for quotes

- Instantly view online the total units, sales dollars, margin & margin % for customers

- Open quote or sales order reports can be automatically Emailed to sales staff

- Daily sales report can be automatically sent to management and sales staff

Contact Us

Request a Demo

Request a demo today to learn how our ERP software, Steel Manager III, can transform your steel distribution and processing operations and increase efficiency throughout your entire supply chain.